-

Notifications

You must be signed in to change notification settings - Fork 83

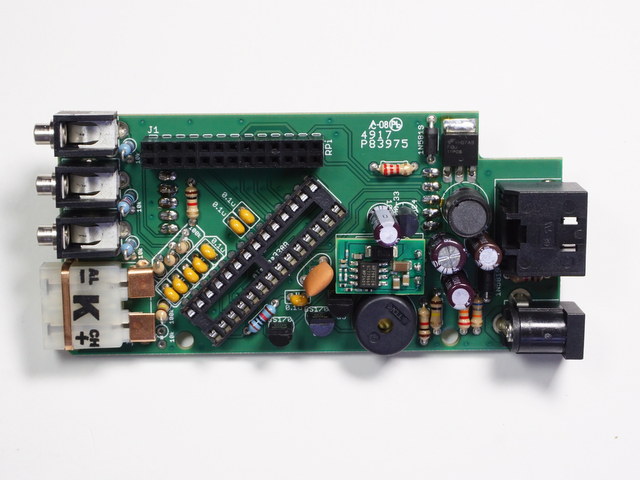

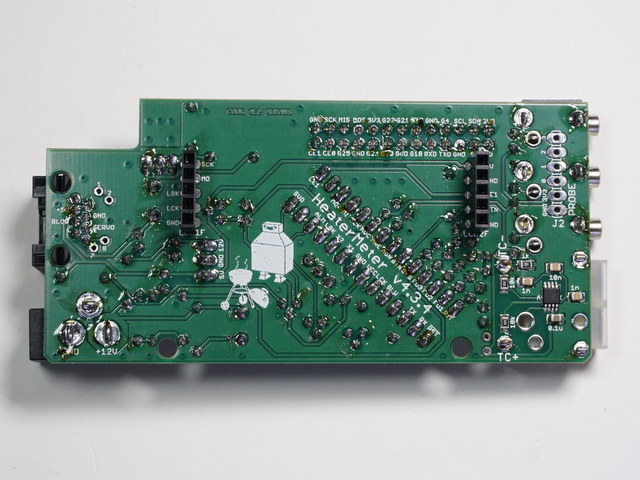

HeaterMeter 4.3 Base Board Assembly

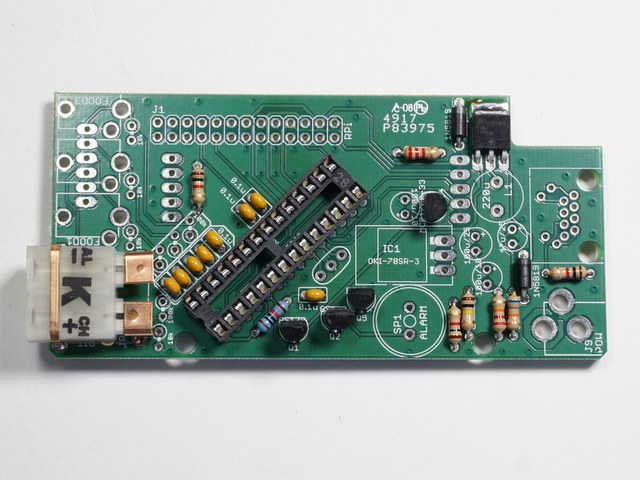

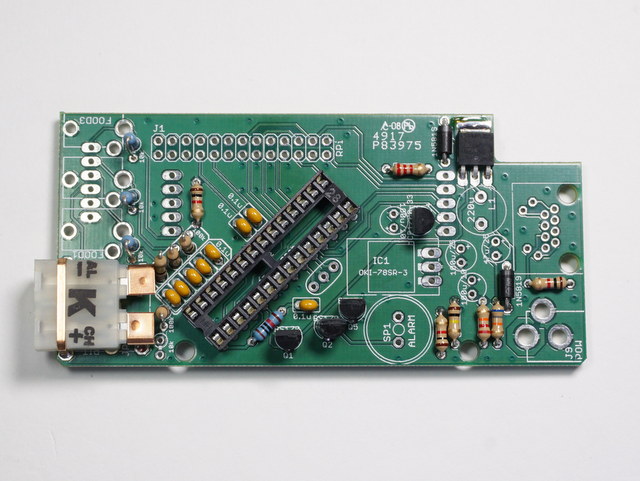

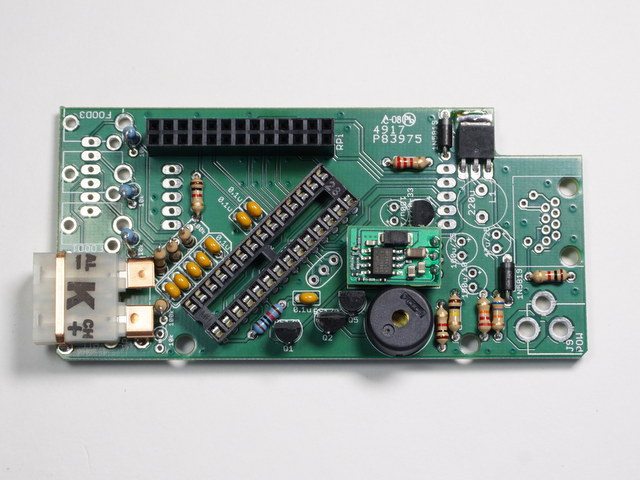

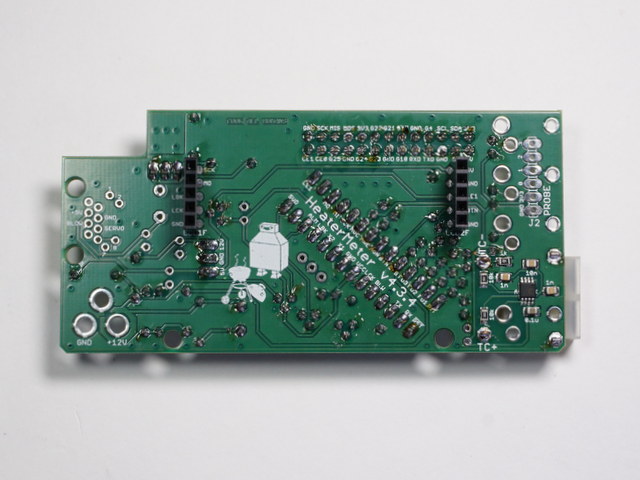

For the HeaterMeter v4.3 Base board, almost all components are soldered on one side. The white silkscreen outlines indicate the component footprints where they should placed, which is on the underside of the board (the side opposite the "HeaterMeter v4.3.x" text and boxy robot logo). The components can go on in any order, but the easiest way to solder them is to start with the components with the lowest height and work your way to the taller pieces.

| Qty | Value | Device | Parts |

|---|---|---|---|

| 3 | 1k | R-US_0204/7 | R1, R3, R21 |

| 1 | 2k2 | R-US_0204/7 | R14 |

| 1 | 10k 1% | R-US_0207/7 | R20 |

| 1 | 22k | R-US_0204/7 | R4 |

| 1 | 68k | R-US_0204/7 | R13 |

| 1 | 100k | R-US_0204/7 | R19 |

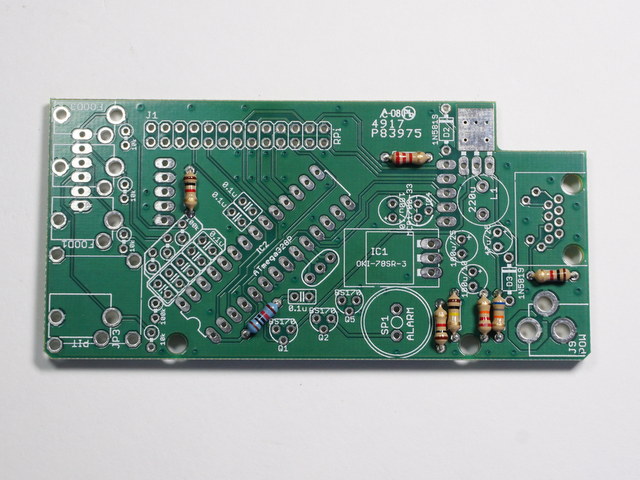

Step 1 Horizontally-mounted resistors. The orientation on these does not matter-- either lead can go in either hole, as long as the body of the resistor is on the right side of the board. The placements are sized such that you should be able to fold the leads of the resistor against the body at a right angle and have them just fit into the holes. It is fastest to insert a couple resistors at a time and flip the whole board over, resting the board on the resistors to hold them in place while you solder them and clip the extra leads off. You will have 4x 100k resistors and 4x 10k resistors left over to be used later.

| Qty | Value | Device | Parts |

|---|---|---|---|

| 8 | 0.1u | C-US025-025X050 | C1, C2, C3, C7, C15, C16, C17, C18 |

Step 2 Ceramic capacitors. These are small yellow blobs and also have no polarity, so their orientation does not matter. There isn't enough room adjacent to the capacitors in the block nearest the ATmega328 to put a label on each one, so be sure to populate each of the footprints in the "0.1u" block with a capacitor in addition to the three fully-labeled footprints (8 total placements).

| Qty | Value | Device | Parts |

|---|---|---|---|

| 1 | FQU11P06TU | MOSFET-P | Q3 |

| 2 | 1N5819 | 1N5819 | D2, D3 |

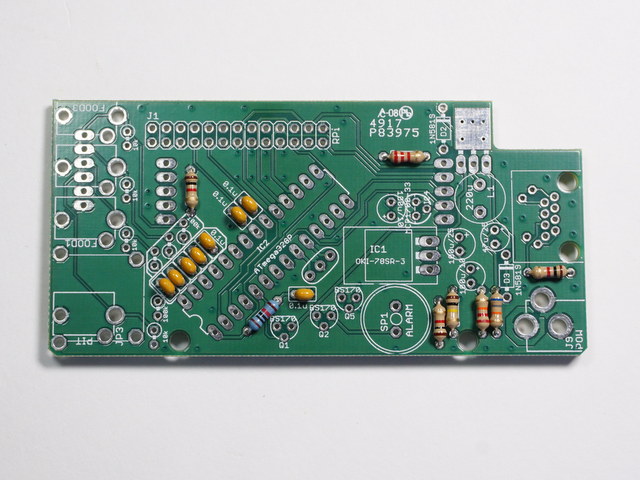

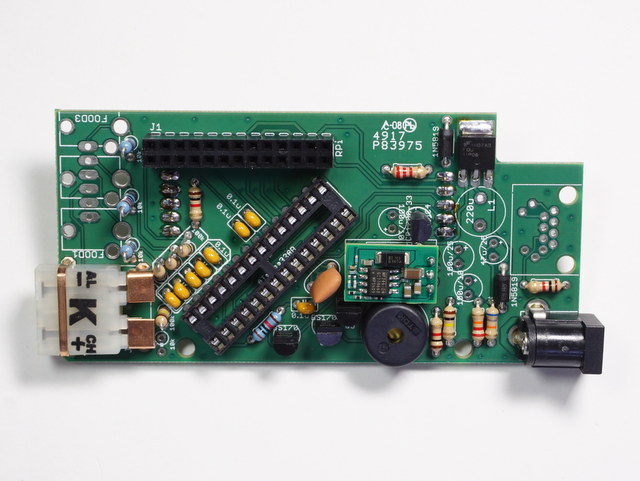

Step 3 MOSFET and Diodes. The power MOSFET Q3's leads can be easily formed to the right dimensions by simply inserting it into its hole then bending it down into position. Soldering the tab of the MOSFET to the PCB is not required for the standard blower. The rectifier diodes have a white line on them to indicate their polarity and should be installed so their white line matches the white line marking on the PCB. Both diodes are identical, either diode can go in either footprint.

| Qty | Value | Device | Parts |

|---|---|---|---|

| 1 | DIP28 | DIP28 | IC2-SOCK (optional) |

| 3 | BS170 | BS170 | Q1, Q2, Q5 |

| 1 | MCP1700-33 | MCP1700-33 | IC4 |

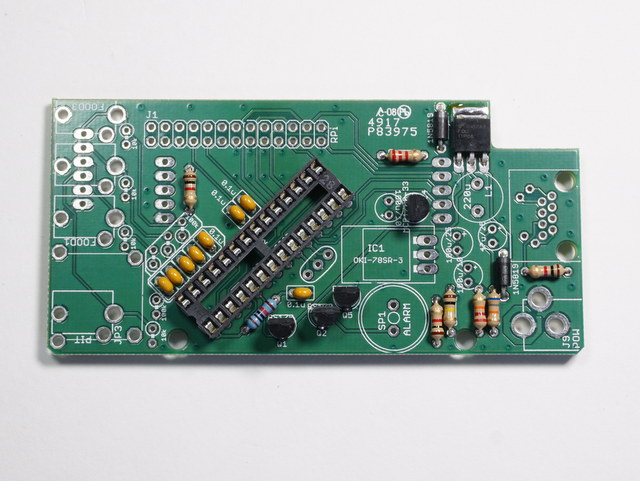

Step 4 IC socket (optional), signal MOSFETs, 3.3V regulator. Install the 28 pin DIP socket for the microcontroller if using this, otherwise install the ATmega328. The both have a notch on one side which indicates the direction it needs to be placed which matches the silkscreen on the footprint. Do not install the ATmega328 chip into socket IC2 at this time if using the socket. The remaining pieces are the parts that look like tiny black water towers with 3 legs. Bend the center lead back at a right angle to the body and then bend it down using your needle nose pliers. The flat front of these devices should be matched to the flat front on the silkscreen of the PCB. Be careful to not mix up the BS170 and MCP1700 parts as they look identical to my naked eyes. The BS170 are identified by having considerably less writing and a little F logo on them.

| Qty | Value | Device | Parts |

|---|---|---|---|

| 1 | PCC-SMP | PCC-SMP-K | J4 |

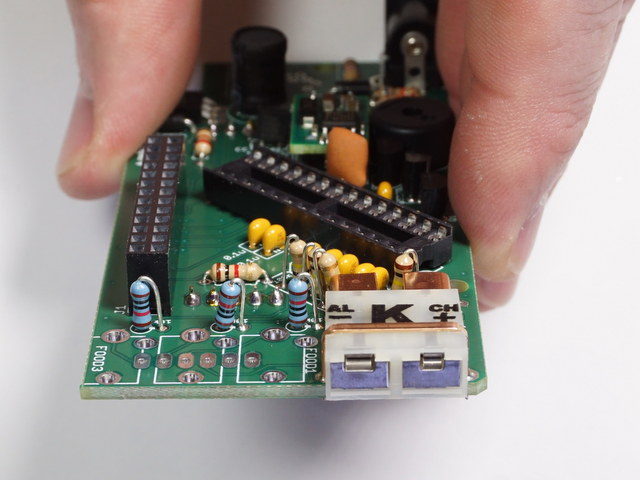

Step 5 If assembling a HeaterMeter with a thermocouple, install the thermocouple jack and copper support strap.

| Qty | Value | Device | Parts |

|---|---|---|---|

| 4 | 10k 1% | R-US_0207 | R5, R16, R17, R18 |

| 4 | 100k | R-US_0204 | R22, R23, R28, R29 |

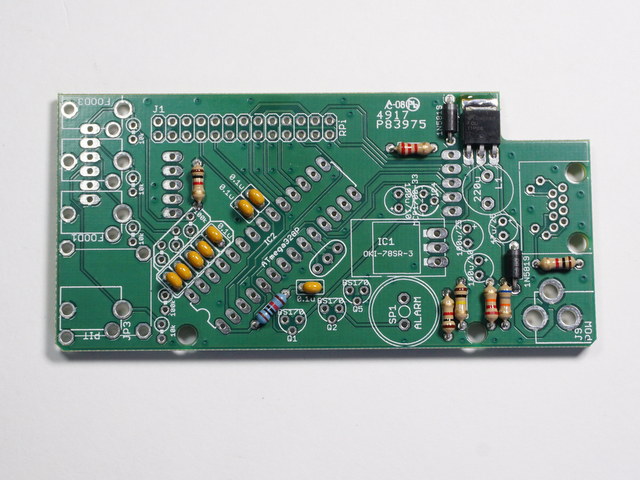

Step 6 The leftover resistors from step 1 are installed now for each of the probe jacks. There isn't enough room on the PCB for the silkscreen for all 100k resistors, so again populate all the resistors in the 100k block. If using a thermocouple, do not install 10k resistor R18 by the pit jack (but do install the 100k).

| Qty | Value | Device | Parts |

|---|---|---|---|

| 1 | ALARM | SPEAKER/AL11P | SP1 |

| 1 | OKI-78SR-5 | OKI-78SR-05H | IC1 |

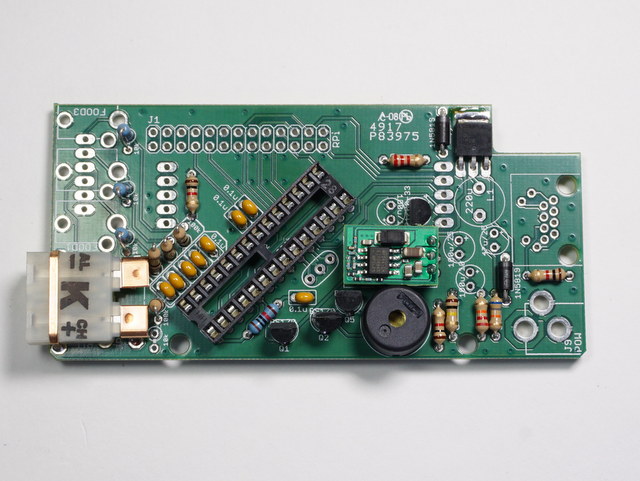

Step 7 The alarm speaker can be installed in any orientation. The 5V regulator module does matter which direction it goes in, just match the silkscreen.

| Qty | Value | Device | Parts |

|---|---|---|---|

| 1 | Pi | PINHD-2X13 | JP1 |

Step 8 26 pin (2x13) Raspberry Pi header. When soldering this, solder one or two pins then check its alignment by looking on the silkscreen side. The white of the silkscreen for its position should just barely be visible on the top side of the connector. Use this to also make sure the connector is straight across left to right and not twisted which would cause the HeaterMeter and Pi boards to not mate in a perpendicular fashion.

| Qty | Value | Device | Parts |

|---|---|---|---|

| 2 | LCD1F, LCD2F | PINHD-1X5 F | JP1, JP8 |

Step 9 - Reverse Side Warning Female LCD/Button board connectors. If assembling a full HeaterMeter with the LCD/Button board, now is a good time to install the 1x5 female pin headers on the base board. They are installed on the opposite side of the board compared to all of these components this far.

| Qty | Value | Device | Parts |

|---|---|---|---|

| 1 | 16MHz | RESONATORRESONATOR-PTH | Y1 |

| 1 | POW | POWER_JACKPTH | J9 |

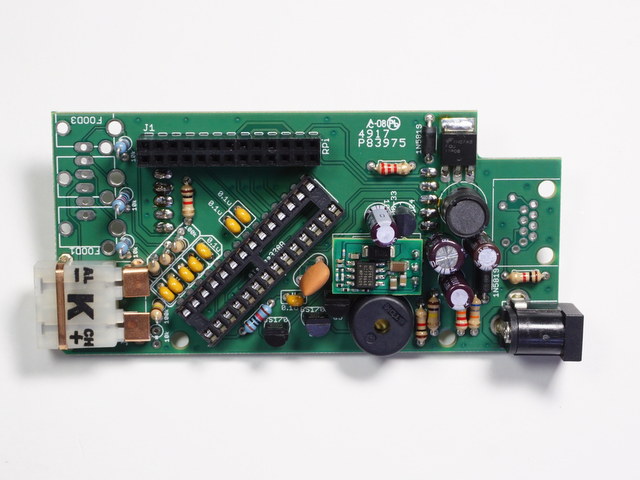

Step 10 Add the larger 3 pin blue blob 16MHz resonator in any orientation (note this used to be orange and is orange in the photo). Next is the Power jack. You'll be putting stress on this jack, inserting and removing the power plug all the time, so be sure to fill in the holes with solder completely to make a more secure physical connection. If this component is too a tight fit, it is the 12V pin on the back of the connector that is the problem. It is a little bigger than the other pins. Just place your soldering iron tip on it so it is hot when inserted and it will melt the solder finish on the PCB hole to let it slip in.

| Qty | Value | Device | Parts |

|---|---|---|---|

| 1 | 220u | INDUCTOR9MM | L1 |

| 1 | 100u/25 | CPOL-USE2.5-6 | C4 |

| 2 | 100u/10 | CPOL-USE2.5-5 | C5, C6 |

| 1 | 47u/25 | CPOL-USE2.5-5 | C12 |

Step 11 Inductor. This mystery black plastic-coated coil also has no polarity, insert it in any haphazard manner. The capacitor "cans" have a line going down the side which indicates the negative side, the PCB has a teeny plus symbol to indicate the positive side. Use deductive reasoning to ascertain the correct orientation. Be careful! Three of the capacitors face one direction, and the fourth faces the opposite direction. Inserting one of these backwards is a dead short and will result in things getting melty on you.

| Qty | Value | Device | Parts |

|---|---|---|---|

| 1 | RJ45-8 | RJ45-8 | JP2 |

| 1-4 | Probes | AUDIO-MONO | JP3, JP4, JP5, JP6 |

Step 12 Rounding out the bottom-side assembly are the remaining I/O jacks. You're in the home stretch now. Do not install JP3 if creating a thermocouple variant.

The HeaterMeter base board is now complete. The board can be tested by installing the ATmega chip into the socket, attaching it to the Raspberry Pi and booting it, or continue to the HeaterMeter 4.3 LCD/Buttton Board Assembly.